Mechanical Design Engineer, Scaling

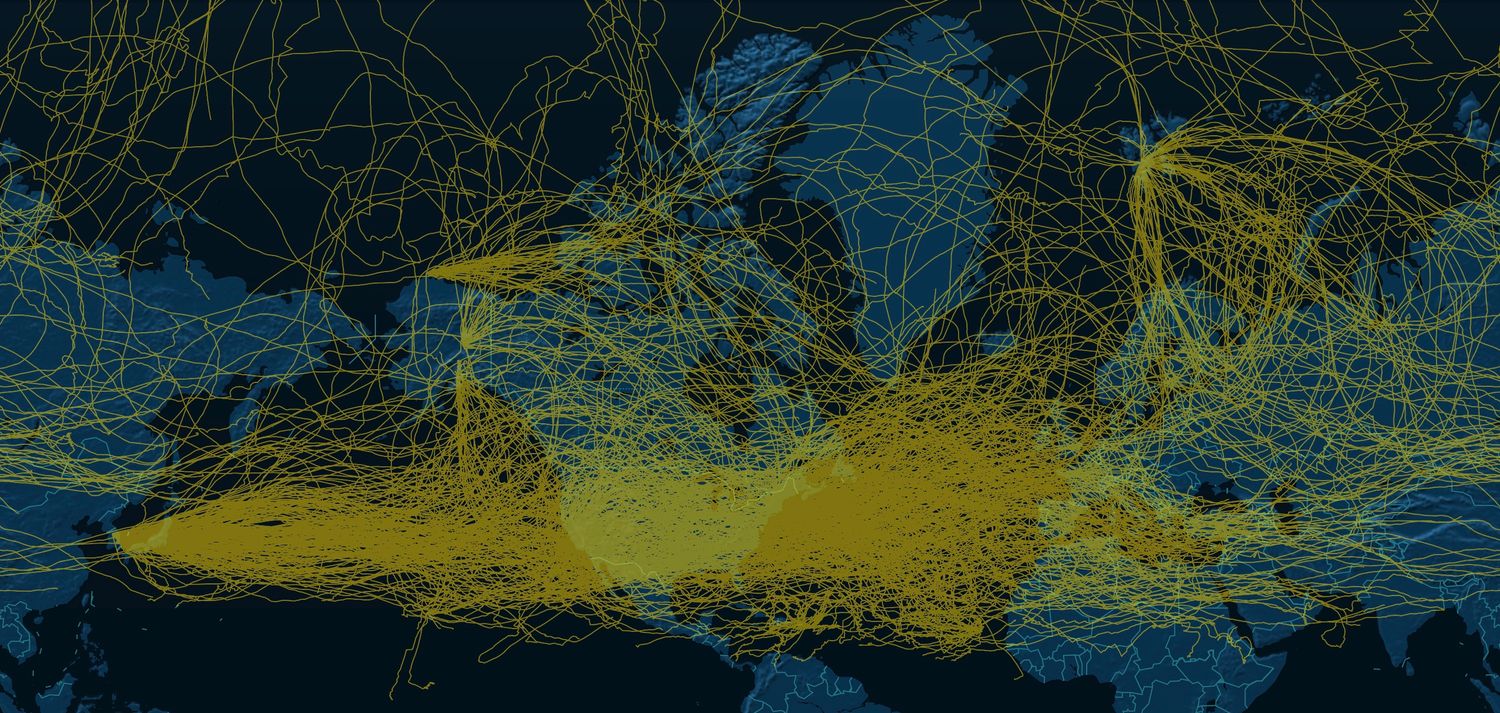

WindBorne Systems is supercharging weather models with a unique proprietary data source: constellations of next-generation smart weather balloons targeting the most critical atmospheric data. We then combine that unique data source with the world’s most accurate AI weather models. Our long-term vision is to eliminate weather uncertainty, and in the process help humanity adapt to climate change, be that predicting hurricanes or speeding the adoption of renewables. The founding team of Stanford engineers was named Forbes 2019 30 under 30 and is backed by top investors including Khosla Ventures.

WindBorne is looking for a Mechanical Design Engineer, Scaling to help us scale from producing tens of units a month to producing hundreds and eventually thousands. This includes designing, optimizing and maintaining both flight hardware and the tools and procedures used to build them.

We're dedicated to both mitigating climate change and helping humanity adapt to its effects as fast as possible, and you can be a part of our mission to make this global societal impact. If you like the idea of working on cutting edge technology, and working with a fast moving team, WindBorne is the place for you.

We believe scaling a hardware platform is one of the hardest problems in engineering and having tight integration between design and manufacture is critical to get orders-of-magnitude increases in performance. This is also why we design and manufacture everything from our own balloon envelopes to the actuators and sensors – it allows us to push the envelope (:D) but requires people who can hold the entire system in their heads.

This is the person we are looking for – a brilliant engineer with the ambition and creativity to tackle this challenge, own our hardware stack and scale our processes by 100x. You will operate on all levels of that stack, working in lockstep with both technicians and the CTO to rethink our designs, tools, and procedures from the ground up.

We expect that for the first several months this role will entail designing production tooling for existing hardware and learning about the platform before taking over platform design and co-optimizing it with the manufacturing process. This is not an easy role –but if you think you’re up to the challenge, we’d love to hear from you.

Responsibilities

Co-optimize the design of the manufacturing process and the hardware design of the platform

Design and implement manufacturing tooling to support the efficient production of global sounding balloons

Identify manufacturing issues and design and implement solutions to improve manufacturability

Respond to failures on the production line. Troubleshoot and determine if they are best solved with tools design, platform design or procedure changes

Implement new procedures and set up manufacturing stations

Interface with technicians to teach new procedures and tools

Skills and Qualifications

Required

Bachelor’s degree or higher in an Engineering field such as Mechanical Engineering

Proficiency in mechanical CAD and 3D modeling (we use SolidWorks)

Experience with rapid prototyping tools like 3D printing, laser cutting

Experience in transitioning hardware from prototype to production

Experience working with outside manufactures and suppliers

Basic proficiency with the Linux operating systems

Excellent communication skills

Meticulous attention to detail

Exceptional mechanical (and electro-mechanical) design intuition.

Being the type of person who enjoys coming up with out of the box solutions to problems with seemingly obvious (but suboptimal) answers

Nice to have

Previous experience in manufacturing, including Quality Control (QC) and Design for Manufacturability (DFM).

Experience designing PCBs (eg using Altium)

Familiarity with PCB and PCBA manufacturing processes.

Ability to automate hardware production processes and tests through code

Familiarity with standard electronic test equipment, including multimeters, oscilloscopes, and power supplies.

Knowledge of surface-mount soldering techniques.

Benefits

- 401(k)

- Dental insurance

- Health insurance

- Vision insurance

- Unlimited PTO

- Stock Option Plan

- Office food and beverages

Location

Address: 858 San Antonio Rd, Palo Alto, CA.

The position is in-person.

What our hardware looks like